Stamping

Our Precision Stamping Capabilities

Our comprehensive array of capabilities in precision metal stamping empowers us to effectively manage stringent tolerances, unique demands, and rapid turnarounds. We thrive in delivering precision metal stamping that aligns with your specifications punctually, without fail.

Seeking Distinct Metal Stamping Solutions?

We hold a strong affinity for specialized requirements and possess extensive proficiency in navigating a diverse spectrum of specifications and constraints relevant to the components we manufacture. This includes:

In-house Design & Build Tooling

Short to Medium Run Metal Stampings

Hold Tight Tolerances

Laser 3-Axis for Short Run / Prototypes

Heat Treated & Plated Parts

Adaptable to Meet Expedited Lead Times

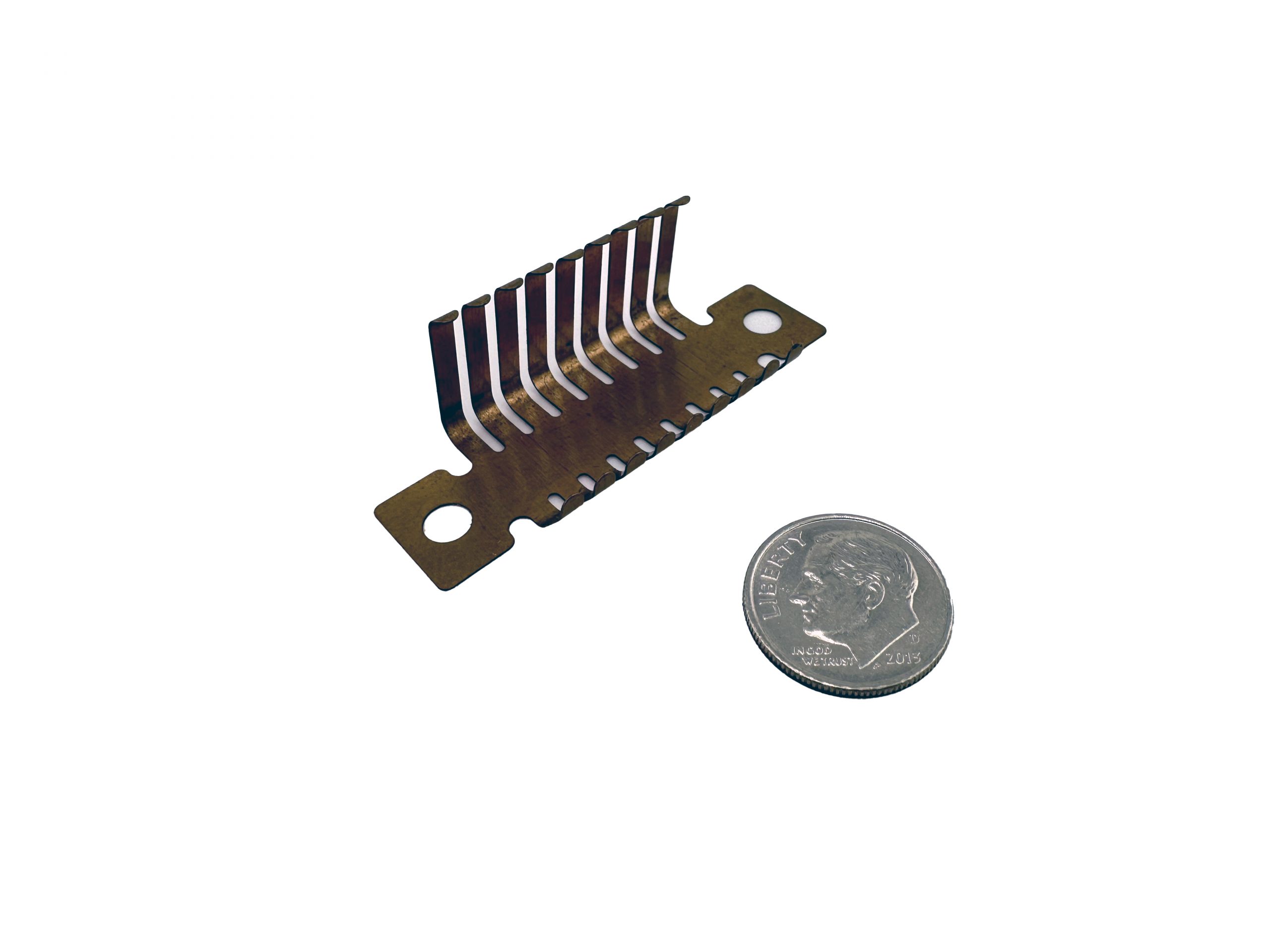

Progressive Stamping

Progressive stamping is a highly efficient manufacturing process ideal for high-volume production. Coil-fed material moves through a stamping press equipped with progressive dies, completing multiple operations with each press stroke. This approach delivers finished parts at high speed while maintaining tight tolerances and consistent quality. Morrissey’s progressive stamping capabilities help customers reduce per-part costs without sacrificing precision or reliability.

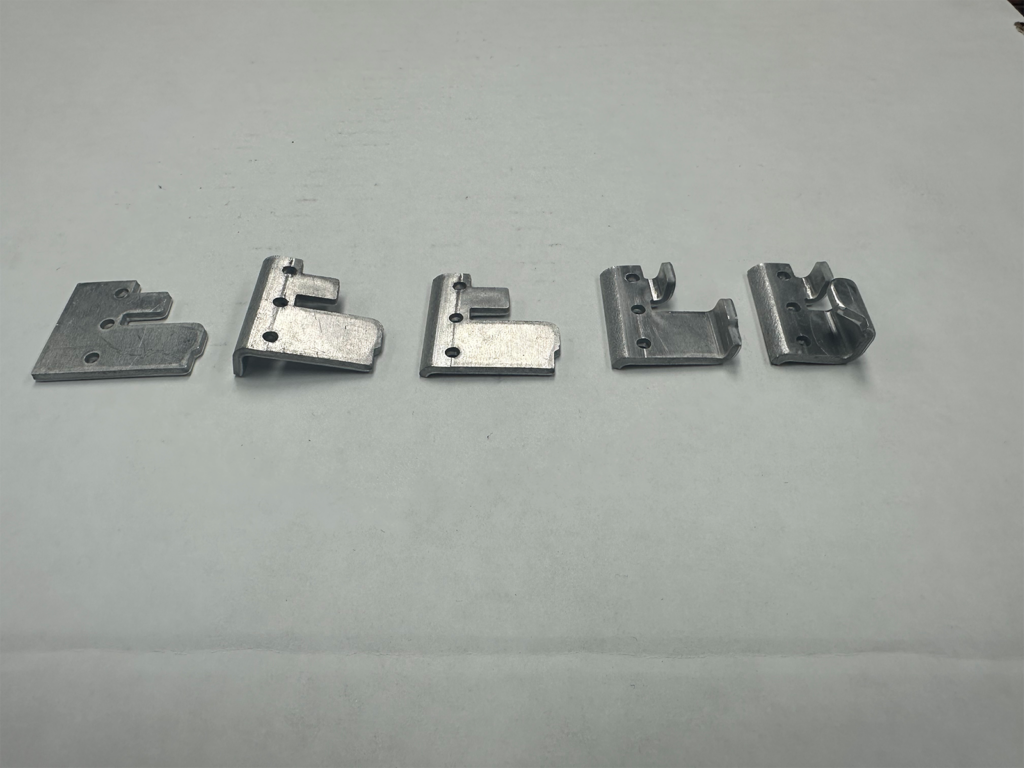

Modular Stamping

Modular stamping offers a flexible approach for projects that require adaptability without the cost of dedicated progressive tooling. By using modular die components, Morrissey can quickly configure tooling to support design changes, varying part requirements, or moderate production volumes. This method shortens lead times and lowers upfront tooling investment while still delivering repeatable, production-ready parts. Modular stamping is an ideal solution for evolving programs and cost-conscious manufacturing.

Deep Draw Stamping

Deep draw stamping forms flat metal into deep, seamless shapes while preserving material strength and dimensional accuracy. The process is well-suited for components requiring durability, consistency, and clean finishes. Morrissey’s deep draw capabilities support complex geometries and repeatable production across a range of materials. This results in high-quality parts built to perform in demanding applications.

Get In Touch

Experience precision in every detail. Reach out to us for a custom quote, and let us forge the perfect solution for your next project. We will follow up with you within 24 hours.