Machining

Our Precision Machining Capabilities

We provide our customers with more than turnkey contract manufacturing and machining. We provide CNC Machining services with a level of quality and precision that will make Morrissey Inc. not simply a one-time supplier of CNC machining, but a trusted source for years to come.

Precise CNC Machined Components Meeting Stringent Standards

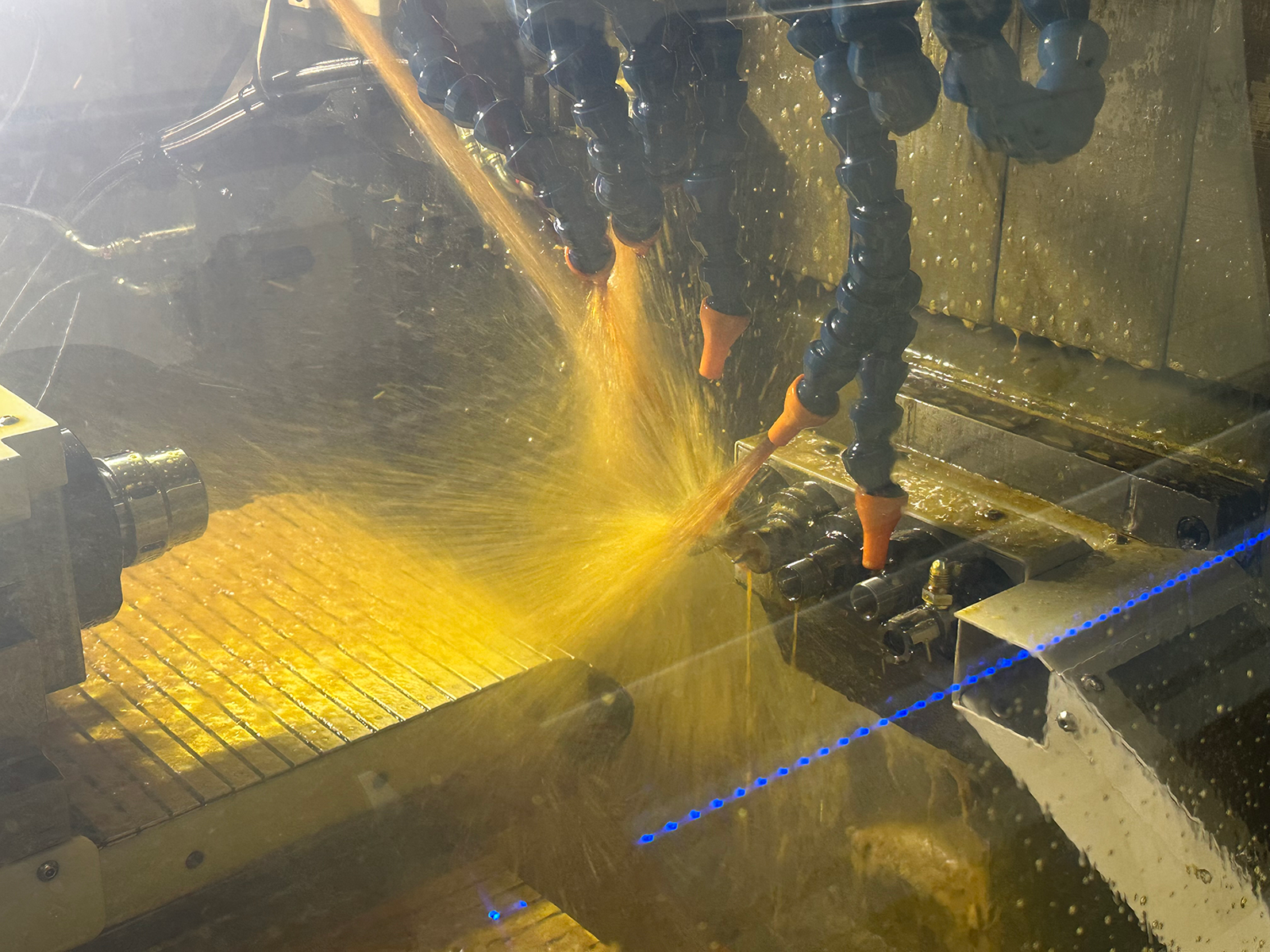

Our CNC Machining offerings at Morrissey, Inc. encompass a spectrum of capabilities:

CNC Milling - Vertical & Horizontal Machining Centers

3 & 4 Axis for CNC Milling Projects

CNC Turning - Swiss Lathes

Blanket or Short Run Orders

Stamped or Lasered Parts with Secondary Machining Operations

Capabilities with Aluminum, Alloy Steels, & Brass

CNC Machine Components

CNC machining produces precise, repeatable components for a wide range of industrial applications. Using advanced CNC equipment, Morrissey machines parts to exact specifications while maintaining tight tolerances and consistent quality. This capability supports both standalone components and secondary operations for integrated assemblies. The result is reliable performance from prototype through production.

5-Axis Machining

Integrated robotic machining enhances efficiency and consistency for higher-volume or repeat production runs. Automation allows parts to be loaded, machined, and unloaded with minimal variation, supporting lights-out manufacturing when required. Morrissey’s robotic integration improves throughput while maintaining precise quality standards. This approach helps control costs while ensuring dependable results.

Integrated Robotic Machining

Integrated robotic machining enhances efficiency and consistency for higher-volume or repeat production runs. Automation allows parts to be loaded, machined, and unloaded with minimal variation, supporting lights-out manufacturing when required. Morrissey’s robotic integration improves throughput while maintaining precise quality standards. This approach helps control costs while ensuring dependable results.

Precision Swiss Turned Machining

Swiss turning is designed for small, high-precision parts requiring exceptional accuracy and surface finish. By supporting the workpiece close to the cutting tool, this process minimizes deflection and maintains tight tolerances. Morrissey’s Swiss machining capabilities are well-suited for complex, tight-tolerance components produced in both moderate and high volumes. The result is precision you can rely on for critical applications.

Precision Turned Parts

Precision turning produces round or cylindrical components with exact dimensional control. Morrissey’s turning capabilities support a wide range of diameters, materials, and tolerance requirements. This process delivers consistent, high-quality parts for both custom and repeat production. Each part is machined to meet performance and reliability expectations.

Custom Turned Screws

Custom turned screws are engineered to meet specific application and performance requirements. Morrissey manufactures screws with unique thread profiles, head styles, and material specifications to match customer designs. This capability ensures proper fit, strength, and repeatability in demanding environments. Custom solutions help eliminate compromises and improve overall product performance.

Get In Touch

Experience precision in every detail. Reach out to us for a custom quote, and let us forge the perfect solution for your next project. We will follow up with you within 24 hours.